Bioreactors are defined as: “An apparatus used to carry out any kind of bioprocess; examples include fermenter or enzyme reactor “. Bioreactors are systems designed to provide a suitable environment for cells of their components to transform substrates into products.

The devices are fundamental for industrial bioprocesses because they can precisely regulate crucial factors, such as temperature. pH, oxygen, and nutrient availability. This fine control allows for the optimization of cell growth, enhancement of productivity, and consistent product quality.

Among the products that bioreactors can produce are fermented edible products and beverages (cheese, beer) to high-added value products (vaccines, antibiotics, biofuels). Bioreactors play a significant role in engineering processes like wastewater treatment and bioremediation.

BioXplorer 100 | bench-top, parallel 8 bioreactor platform

The BioXplorer 100 is a bench-top, parallel 8 bioreactor platform, typically with 125 ml v

BioXplorer 400 | bench-top, parallel 4 bioreactor platform

The BioXplorer 400 boosts productivity and enables screening of cell culture conditions in

BioXplorer 5000 | Lab-scale bioreactor platform

The BioXplorer 5000 bioreactor is ideally suited to drive your cell culture scale-up eff

History of bioreactors

Bioreactors have been brought to the fore of biotechnological processes. However, bioreactors have accompanied humanity for the last 10000 years. The first scientific evidence of vessels used for fermentation dates circa 7000 BC in China. It consisted of a clay pot, and analysis of the organics trapped in the clay revealed the product of fruit juice, rice, and honey fermentation.

The evolution of bioreactors in ancient history was closely intertwined with advancement in food fermentation, including the first evidence of wine in Iran (5500 BC), first leavened bread in Egypt (3000 BC), pickled cucumber in Iran (2000 BC).

Antibiotic discovery by Ian Fleming in 1928 revolutionized modern bioreactors. Although the first evidence of the use of antibiotics dates from 500 BC in China – moldy tofu curds -it took over 2000 years to identify that it was penicillin, which prevented the wounds from being infected. The production of penicillin after Fleming’s discovery was a time and resource-consuming task, which involved using whatever containers were available.

Scaling up penicillin production required the design of sophisticated bioreactor systems capable of optimizing the cultivation of Penicillium rubens. Around the time of this serendipitous discovery, scientists such as Chaim Weizmann, Ernst Stauch, and Herbert Schmidt made substantial contributions to bioreactor design. Weizmann designed the first bioreactors used to produce acetone, and Stach and Schmidt developed tubing that allowed the introduction of water and steam in reactors to achieve aseptic conditions. By 1945, the first large-scale bioreactors (20 L) were manufactured, and the demand for penicillin (7 trillion units) was met for the first time.

In the present day, bioreactors play a fundamental role in diverse scientific and industrial applications.

Read More on History of Bioreactors

H.E.L’s BioXplorer

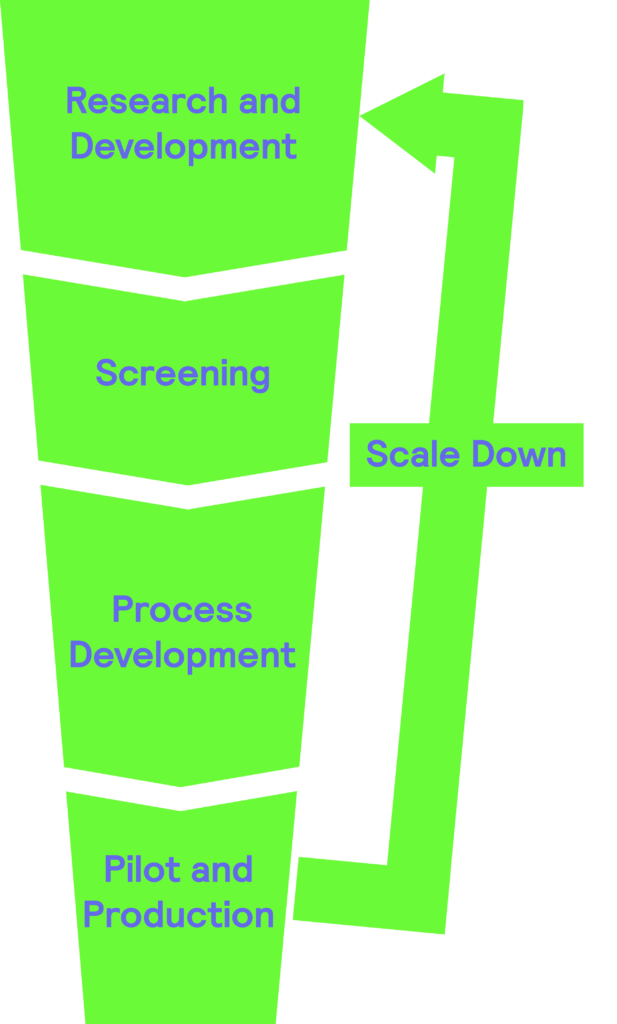

Scale-up and scale-down processes, from Research and Development to Production Scale, are a cornerstone in biotechnological processes.

In Research and Development, it is vital to understand the parameters in which the biological agent used in the bioprocess is viable. The possibility of running independent bioreactors allows faster parameter optimization. Small-volume reactors allow shorter incubation times and reduced costs, which, combined with high throughput miniature reactors, results in shortened project timelines. Using larger volume reactors (up to 5 L) allows for a better understanding of how the process will function at a bigger scale, making process development and pilot scale more reliable and accurate.

By integrating cutting-edge technology and advanced automation, the BioXplorer offers significant efficiency, scalability, and reproducibility advantages. Researchers can accelerate their workflows, optimize yield, and minimize manual intervention, enhancing productivity and reducing time-to-market. The BioXplorer is a robust and reliable partner in advancing biological processes, empowering scientists to unlock the full potential of biotechnology and drive innovation in industries ranging from pharmaceuticals to biofuels and beyond.