Scale-Up

What needs verification before going into industrial scale?

Parameters such as temperature, pH, agitation, and aeration are fundamental and should have been optimized at a smaller scale. Pilot scale processes are an invaluable tool and act as a bridge between laboratory scale and plant scale. However, larger volumes can decrease the efficiency of mass and energy transfer, potentially impacting the productivity and effectiveness of the overall process. This allows for verification that the previous optimization is still valid and, if not, gives the opportunity to tune the variables that result in underperformance. One of the critical aspects to evaluate at the pilot scale is aeration and mixing, which can become challenging at increased volumes, resulting in non-uniform distribution of nutrients and oxygen. This can result in decreased cell growth and product formation.

Pilot scale studies can help to create conditions that mimic the production scale process through testing and refinement. Achieving these conditions can facilitate a smoother transition to industrial-scale production. Moreover, rigorous testing can minimize risk operational and financial setbacks due to unanticipated problems once in full production.

Solutions

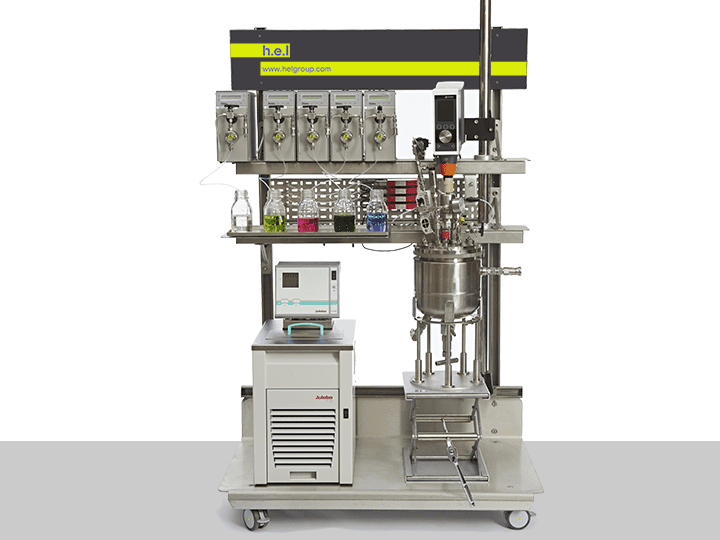

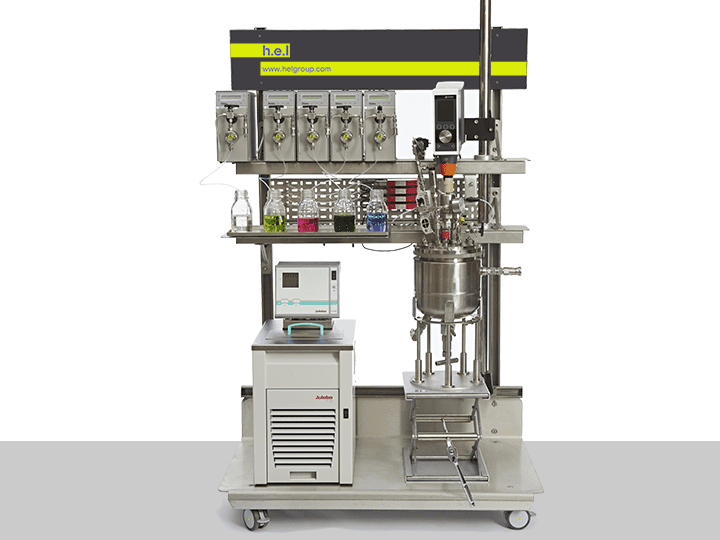

The BioXplorer, especially the BioXplorer 5000, is an excellent platform for scale-up processes. This model can operate at regular or high pressure and up to 5 L volumes. This facilitates a comprehensive understanding of critical processes that can be affected during scaling-up, such as energy and mass transfer at a larger scale. Moreover, it enables the exploration of oxygen and nutrient distribution dynamics, proving its worth as a versatile tool for optimization.

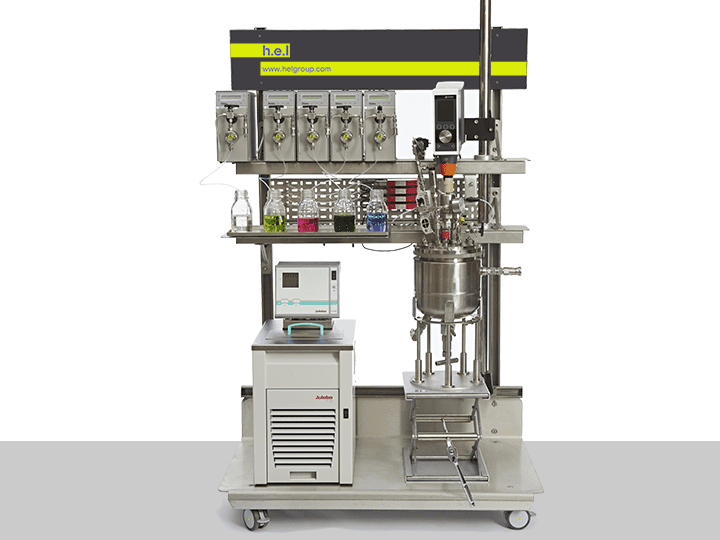

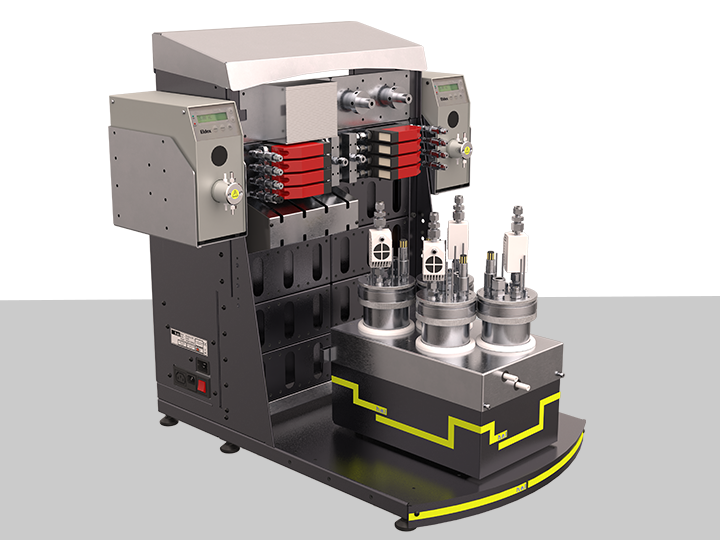

BioXplorer 5000 | Lab-scale bioreactor platform

The BioXplorer 5000 and 5000P single bioreactor systems are ideally suited to drive your s...

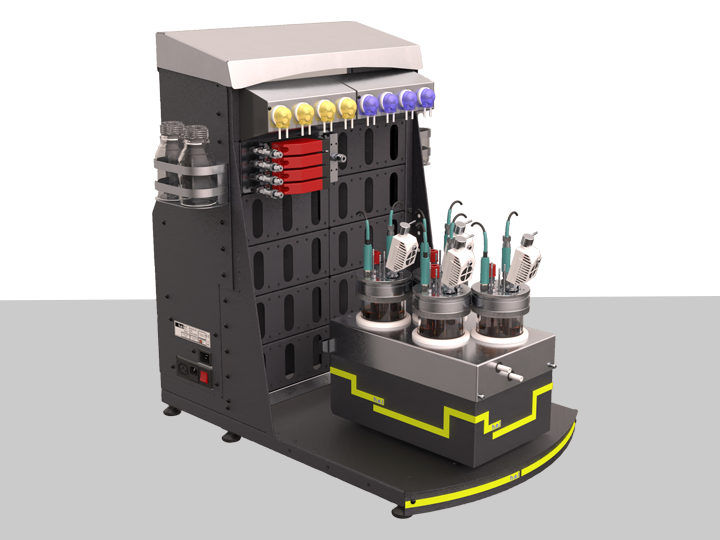

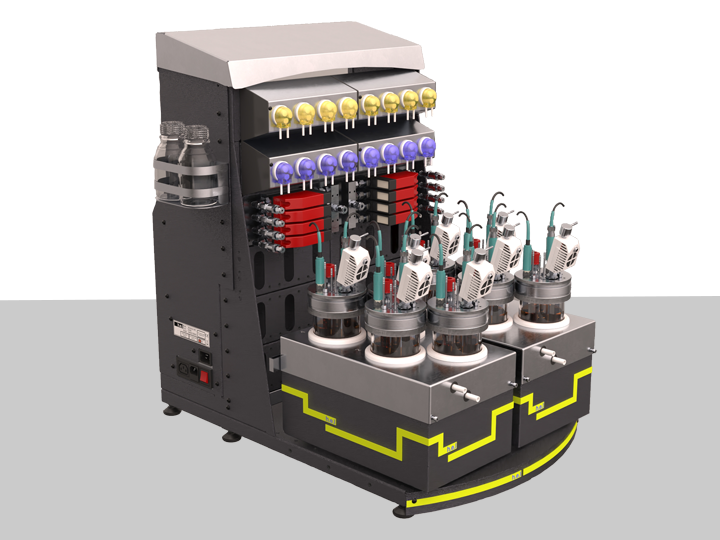

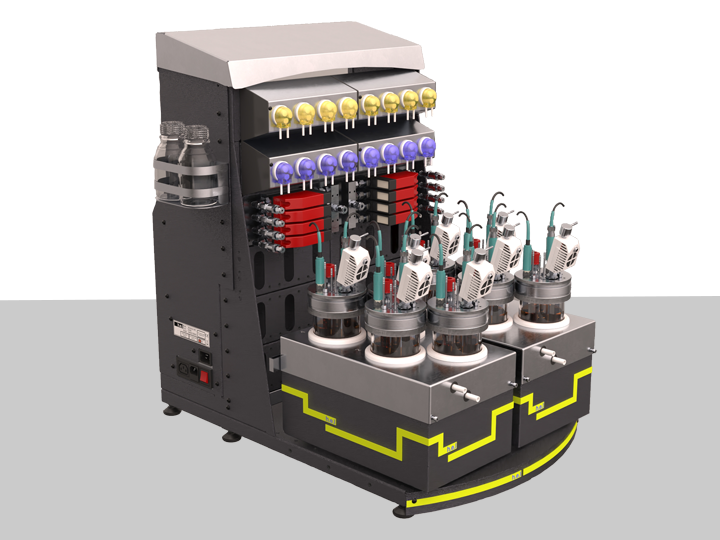

BioXplorer 400 | bench-top, parallel 4 bioreactor platform

The BioXplorer 400 is equipped with 4 bioreactors with working volumes of up to 400 ml. It...

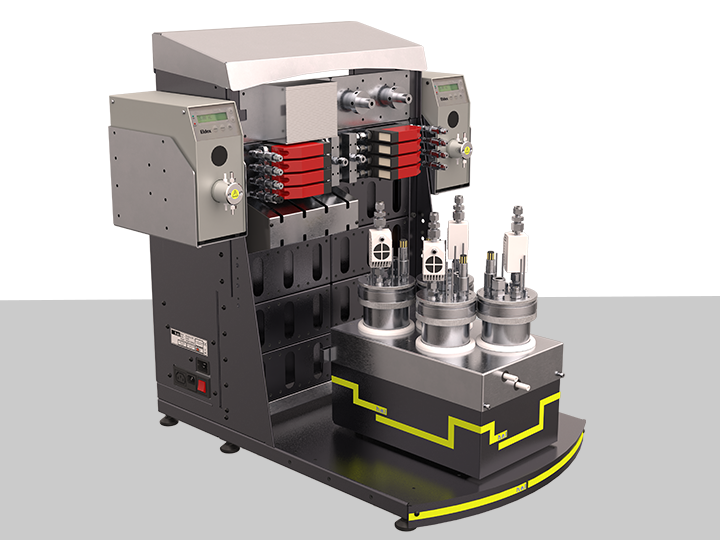

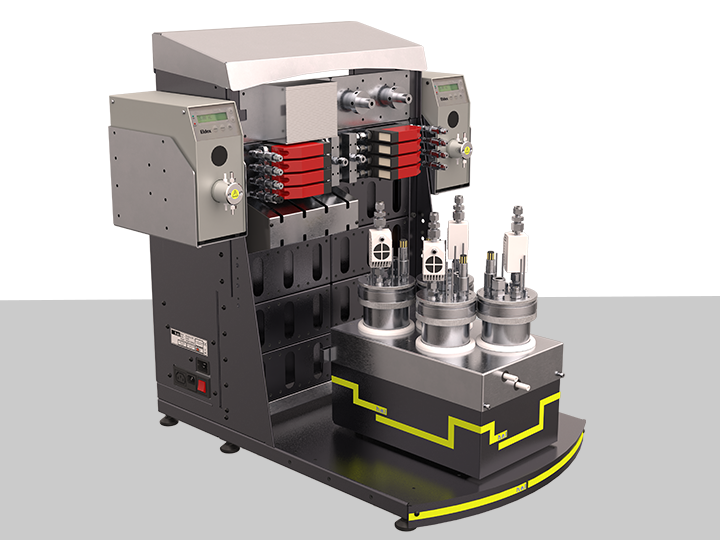

BioXplorer 400P | High-pressure bench-top, parallel 4 bioreactor platform

The BioXplorer 400P is an automated parallel pressure bioreactor system for the discovery ...

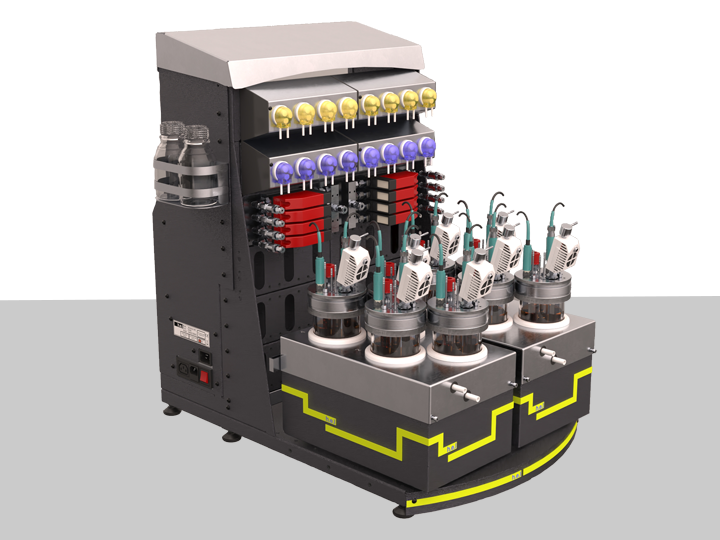

BioXplorer 400XL | Expanded Bench-Top, Parallel 8 Bioreactor Platform

Featuring eight 500 ml bioreactors, the BioXplorer 400XL allows the fast optimization of c...

How do we ensure the consistent quality of the product?

Benchtop and pilot scale experiments can be used to demonstrate the reproducibility of the biological process. Additionally, due to their smaller size, several bioreactors can be run in parallel to check whether the data produced is consistent. This stage is fundamental in verifying the robustness of the process, which is a crucial requirement when adhering to Good Manufacturing Practices (GMP).

At this stage, numerous batches must be run to demonstrate reproducible and consistent results in yield, product quality, and other critical characteristics under defined operating conditions. Reproducible processes at the pilot scale increase confidence for the industrial scale and are particularly relevant for regulatory submission.

Consistency, on the other hand, refers to the ability of the bioprocess to generate a product of uniform quality. On a pilot scale, the quality of the product is monitored throughout batches to ensure that parameters such as purity and potency remain constant. This is challenging to the inherent variability of biological systems, but by using strict control and parameters and consistent substrates, this variability can be kept to a minimum.

Solutions

The BioXplorer, especially the BioXplorer 5000, is an excellent platform for scale-up processes. This model can operate at regular or high pressure and up to 5 L volumes. This facilitates a comprehensive understanding of critical processes that can be affected during scaling-up, such as energy and mass transfer at a larger scale. Moreover, it enables the exploration of oxygen and nutrient distribution dynamics, proving its worth as a versatile tool for optimization.

BioXplorer 5000 | Lab-scale bioreactor platform

The BioXplorer 5000 and 5000P single bioreactor systems are ideally suited to drive your s...

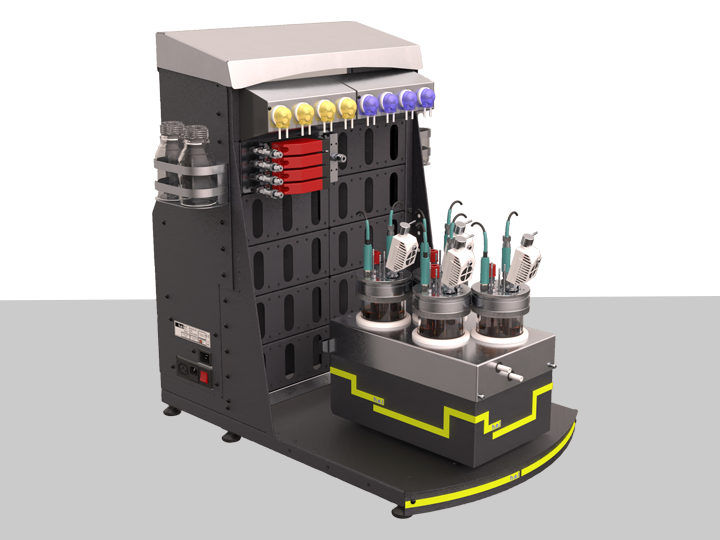

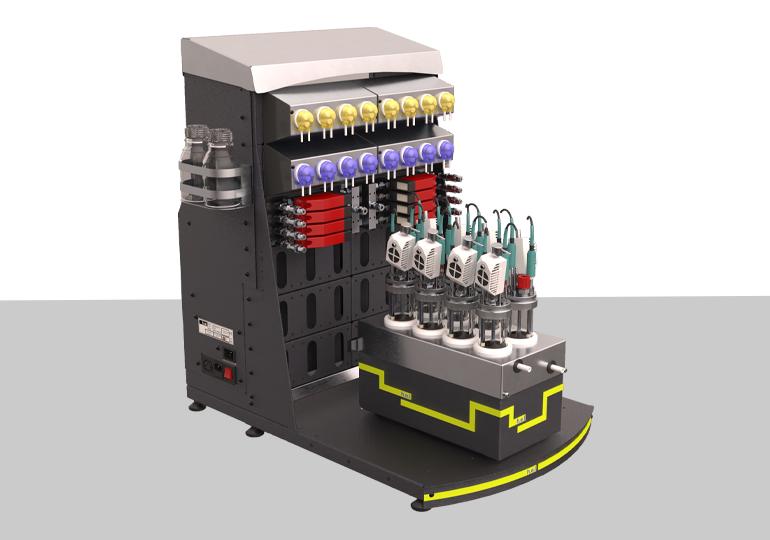

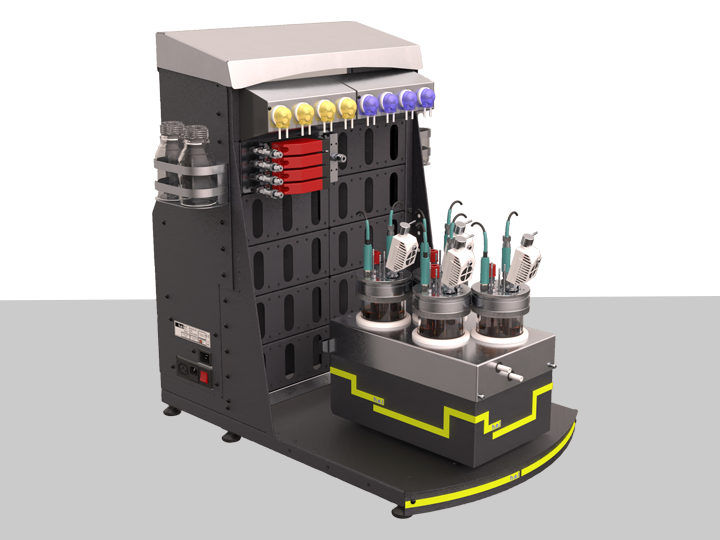

BioXplorer 100 | bench-top, parallel 8 bioreactor platform

The BioXplorer 100 is a multi-bioreactor system designed for the optimization of aerobic f...

BioXplorer 400 | bench-top, parallel 4 bioreactor platform

The BioXplorer 400 is equipped with 4 bioreactors with working volumes of up to 400 ml. It...

BioXplorer 400P | High-pressure bench-top, parallel 4 bioreactor platform

The BioXplorer 400P is an automated parallel pressure bioreactor system for the discovery ...

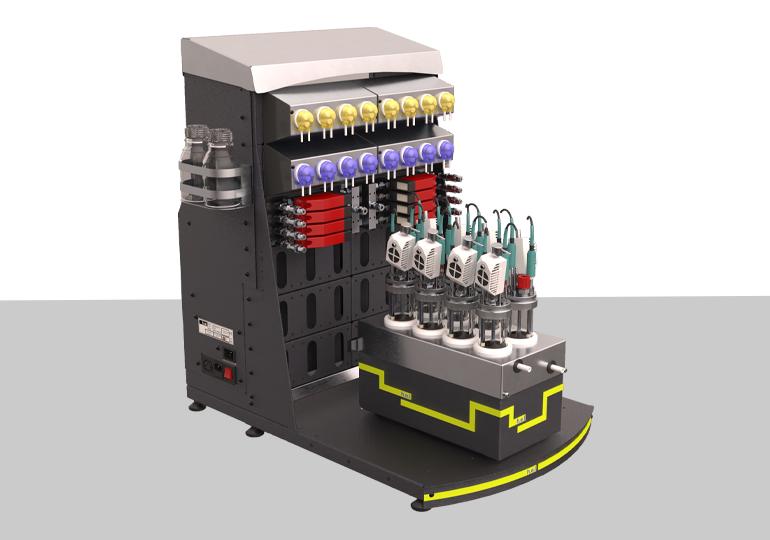

BioXplorer 400XL | Expanded Bench-Top, Parallel 8 Bioreactor Platform

Featuring eight 500 ml bioreactors, the BioXplorer 400XL allows the fast optimization of c...

How can the pilot scale help reduce future risks?

At a pilot scale state, bioprocesses are tested under conditions that mimic industrial-scale operation. However, their smaller size offers a more manageable and controllable environment. This can provide a safety net; if issues arise, they can be addressed more cost-efficiently than at a full industrial scale. Thus, the pilot scale can serve as a crucial checkpoint, allowing for the early identification and correction of problems.

The pilot scale also can function as the training ground for operators, allowing them to familiarize themselves with the intricacies of process dynamics, equipment, and controls. This familiarization process can be helpful and reduce the risk of operation error, leading to safety incidents at full-scale production. Additionally, the data generated during the pilot stage can be used to validate the process.

Solutions

The BioXplorer, especially the BioXplorer 5000, is an excellent platform for scale-up processes. This model can operate at regular or high pressure and up to 5 L volumes. This facilitates a comprehensive understanding of critical processes that can be affected during scaling-up, such as energy and mass transfer at a larger scale. Moreover, it enables the exploration of oxygen and nutrient distribution dynamics, proving its worth as a versatile tool for optimization.

BioXplorer 5000 | Lab-scale bioreactor platform

The BioXplorer 5000 and 5000P single bioreactor systems are ideally suited to drive your s...

BioXplorer 100 | bench-top, parallel 8 bioreactor platform

The BioXplorer 100 is a multi-bioreactor system designed for the optimization of aerobic f...

BioXplorer 400 | bench-top, parallel 4 bioreactor platform

The BioXplorer 400 is equipped with 4 bioreactors with working volumes of up to 400 ml. It...

BioXplorer 400P | High-pressure bench-top, parallel 4 bioreactor platform

The BioXplorer 400P is an automated parallel pressure bioreactor system for the discovery ...

BioXplorer 400XL | Expanded Bench-Top, Parallel 8 Bioreactor Platform

Featuring eight 500 ml bioreactors, the BioXplorer 400XL allows the fast optimization of c...