Parameter Optimisation

What parameters impact in research and development of biological processes?

Bioreactors, as specialized vessels designed to provide optimal conditions for biological processes, allow the fine-tuning of key parameters. Screening of the optimal parameters is fundamental in bioprocessing as it directly impacts the performance and productivity of biological systems. Bioreactors play a crucial role in this optimization by providing a controlled environment where key parameters such as temperature, pH, oxygenation, nutrient supply, and agitation can be precisely regulated. By optimizing these parameters, researchers can enhance cell growth, metabolism, and product formation, leading to increased yields, improved quality, and efficient scaling up of bioprocesses. Culture conditions also will directly impact culture morphology and physiology, but also will alter which secondary metabolites are produced. Bioreactors are invaluable tools for parameter optimization, enabling researchers to achieve optimal conditions and reliable results in various industries.

Temperature

Temperature directly influences organisms’ growth and metabolic activity, and therefore it will impact the product formation of cells, whether it is metabolites or biomass. The optimization of temperature is thus crucial.

Temperature plays a significant role in cell growth kinetics; optimal values depend on the organism. Deviations from the value result in suboptimal growth rates, extended lag phases, and cell death. Precise adjustment and maintenance of the temperature with a favorable range promotes rapid and efficient cell growth, leading to higher biomass production.

The temperature has an impact on chemical and biochemical reactions and, therefore, will impact enzymatic activity and metabolic pathways. Enzymes exhibit temperature optima at which activity is highest. The fine-tuning of temperature can help to ensure that conditions remain within the ideal range, enhancing enzymatic activity and facilitating the desired biochemical reactions within the bioreactor.

Proteins and other biomolecules’ structural stability and functionality depend highly on temperature. Changes in the value can lead to protein denaturation and loss of activity. Fine control of temperature can ensure structural integrity and functionality of large biomolecules, maximizing their effectiveness in the bioprocess.

In summary, temperature optimization in bioprocesses is vital for promoting optimal cell growth, enhancing enzymatic activity, and maintaining protein stability. By carefully controlling and adjusting the temperature within the bioreactor, researchers can create an environment that maximizes the desired biochemical reactions, leading to improved productivity, yield, and overall process performance.

pH

Medium acidity or alkalinity greatly impacts bioprocess optimization, and precise control of this parameter is crucial for cell growth, metabolism, and product formation.

Enzymatic activity, and therefore metabolic pathways, are strongly dependent on pH. Enzymes exhibit specific pH optima at which their activity is maximized. Deviation from this value results in reduced enzymatic efficiency and, consequently, reduced metabolic activities. By precisely adjusting and maintaining the pH within the optimal range, enzymatic activity can be enhanced, yielding the desired products.

A biomolecule’s structure and stability are heavily influenced by pH due to charge distribution, which determines the conformation of proteins and nucleic acids. Optimization of pH ensures that the aforementioned structures are stable.

Similarly to enzymes, cells have narrow pH ranges at which their growth is optimal. This range will depend on the organism, and variation in this value can be detrimental to the growth due to changes in membrane permeability, nutrient update, and waste product excretion.

Organic compounds can have different solubility values and speciation under different pH values, affecting their bioavailability which can impact cell uptake.

In summary, pH optimization in bioprocesses is critical for maximizing enzymatic activity, preserving biomolecular stability, promoting cell growth, and optimizing substrate availability. By carefully adjusting and maintaining the pH within the appropriate range, researchers can create an environment that facilitates the desired biochemical reactions, improving bioreactors’ productivity, yield, and overall process performance.

Oxygenation

Oxygen concentration is a vital parameter in bioprocess optimization for aerobic (oxygen-dependent) and anaerobic (oxygen-independent) organisms. The volumetric mass transfer coefficient of oxygen (KLa) determines the concentration of oxygen in the medium. This coefficient shows how efficiently oxygen transitions from the gas phase into the liquid phase. In the case of aerobic organisms, oxygen is used for cellular respiration and energy generation; therefore, ensuring an adequate supply is fundamental. On the other hand, oxygen is detrimental for many anaerobic organisms, resulting in slower processes or even cell death. In some processes, the metabolic pathways that would produce target biomolecules are heavily regulated by the presence of oxygen (e.g. facultative fermentations), and a fine control of the oxygen values is crucial.

In some cases, excessive oxygen levels or prolonged exposure to this gas can cause oxidative stress, which results in oxidative damage to biomolecules and cells. Striking the balance between oxygen demand and avoiding oxidative effects can help ensure optimal cell performance.

Furthermore, oxygenation affects mass transfer rates within the bioreactor, influencing the availability of other dissolved gases, nutrients, and waste removal. Optimization of oxygenation parameters, such as agitation speed, aeration rate, or sparging methods, enhances mass transfer efficiency, reducing concentration gradients and ensuring optimal cell growth and product formation.

Optimizing oxygenation in bioprocesses is crucial for facilitating aerobic metabolism, supporting cell growth and viability, and promoting the synthesis of desired products.

Agitation and mixing

Agitation and mixing are critical parameters in bioprocess optimization, ensuring efficient mass, energy transfer, and homogeneous distribution of nutrients and gases. Agitation and mixing are controlled by the design and configuration of the agitation system, such as impeller design, speed, and presence/absence of baffles. These factors influence the rate and pattern of mixing within the bioreactor. Careful selection and optimization of agitation patterns contribute to achieving desired mixing levels, preventing the formation of dead zones or excessive shear forces.

Effective mixing ensures all cells have equal access to nutrients, promoting uniform growth and preventing localized nutrient depletion. Adequate oxygen distribution is fundamental for aerobic processes, preventing anaerobiosis, which results in suboptimal functioning and, eventually, cell death.

Appropriate mixing prevents concentration gradients – nutrient availability, pH, dissolved gases, or waste product accumulation. These gradients can be detrimental to cell growth, metabolism, and product formation. By creating turbulence and promoting fluid movement, contact between cells and the surrounding medium improves, resulting in better nutrient uptake.

Agitation processes heavily impact the temperature inside the reactor. Mixing helps distribute heat from external suppliers, such as heating jackets, and the heat generated by metabolic processes. Localized heat accumulation results in cells stress, impacting growth and metabolic processes.

Nutrient supply

The medium composition and nutrient supply are vital components for optimizing bioprocesses, ensuring that all the essential substances for cell growth, metabolism, and productivity are supplied. The optimization of the medium includes carbon and nitrogen sources and macro and micronutrients. Bioreactors can operate different operation modes, such as batch, fed-batch, or continuous feeding. The selection of the appropriate strategy will impact product formation and growth rate. Optimizing feeding strategies ensures a continuous and balanced nutrient supply throughout the bioprocess, maintaining favorable growth conditions and maximizing productivity.

The possibility of adding measuring probes allows for real-time process monitoring and control, ensuring an optimal nutrient supply. Feedback control systems are utilized to maintain nutrient concentrations within desired ranges, ensuring consistent nutrient supply and promoting optimal cell growth and product formation.

In summary, nutrient supply optimization in bioprocessing encompasses various factors, including selecting and concentrating carbon and nitrogen sources, the provision of macronutrients and micronutrients, media composition, nutrient feeding strategies, process monitoring and control, and waste management. By carefully considering these aspects, researchers can create an environment that supports optimal cell growth, metabolism, and productivity, leading to successful bioprocesses within bioreactors.

Solutions

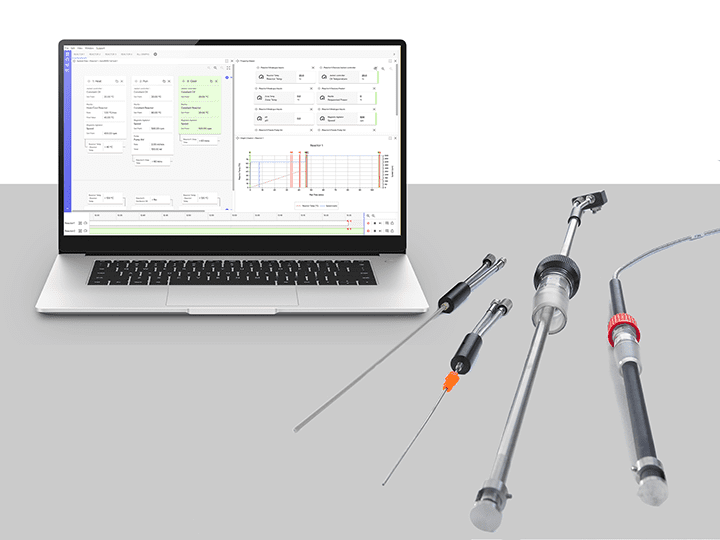

The BioXplorer, one of the flagship products at H.E.L, is incredibly powerful for bioprocess optimization. Its customization capability allows one to choose the probes for specific requirements, providing unparalleled flexibility and precision. Its integration with H.E.L WinISO enables rigorous control over bioprocess conditions, ensuring optimized and reliable workflows.

Regarding the specialized measurements, we offer auxiliary tools from H.E.L, such as BioVIS or Tandem Off Gas Analyzers, integrating seamlessly with the BioXplorer. All these elements combined underscore H.E.L’s dedication to crafting solutions that exceed industry expectations.

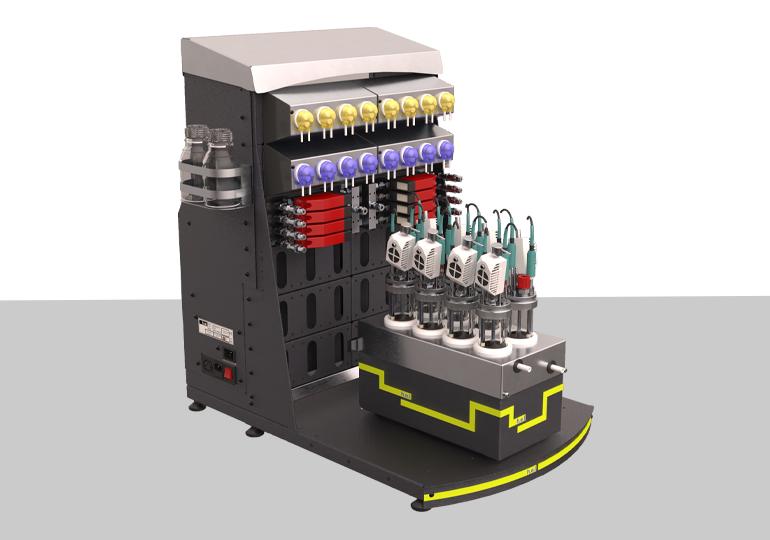

BioXplorer 100 | bench-top, parallel 8 bioreactor platform

The BioXplorer 100 is a multi-bioreactor system designed for the optimization of aerobic f...

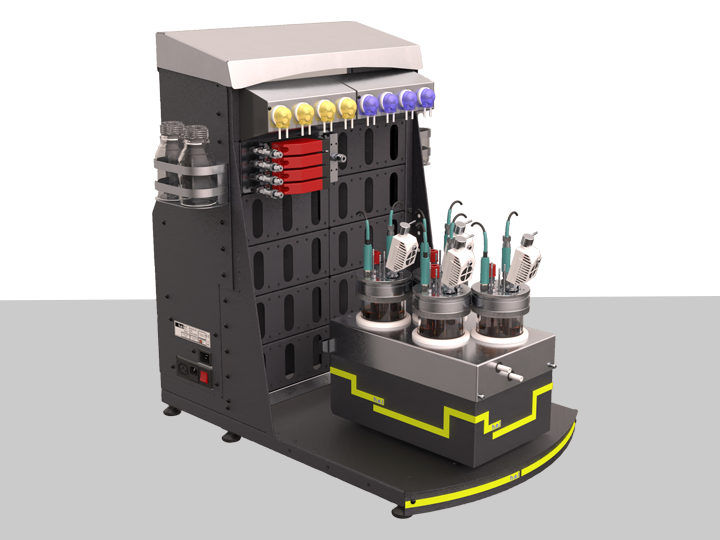

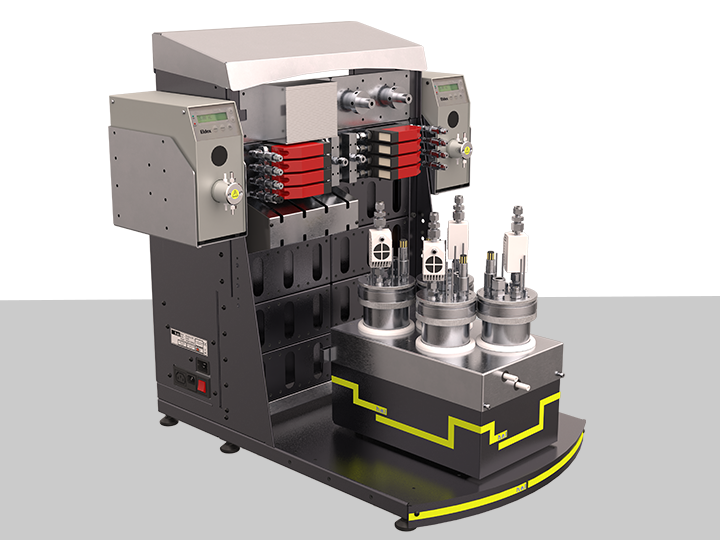

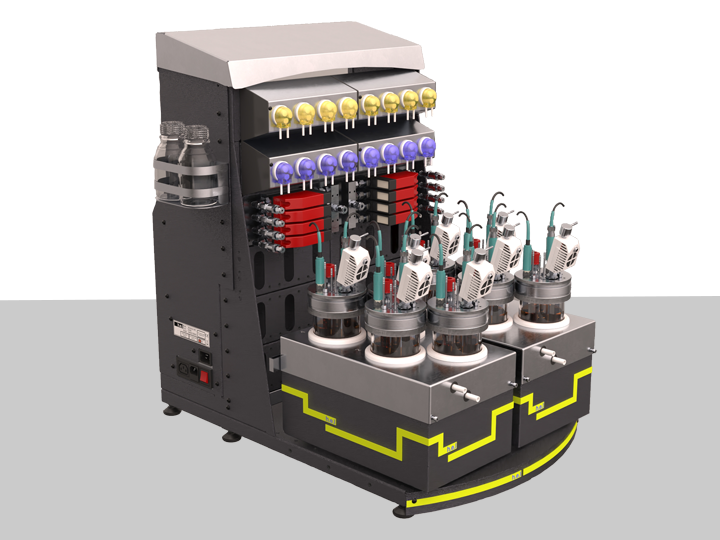

BioXplorer 400 | bench-top, parallel 4 bioreactor platform

The BioXplorer 400 is equipped with 4 bioreactors with working volumes of up to 400 ml. It...

BioVIS | An Inline Cell Density Indicator Sensor

BioVIS is a probe for the inline monitoring of total cell growth and biomass within a bior...

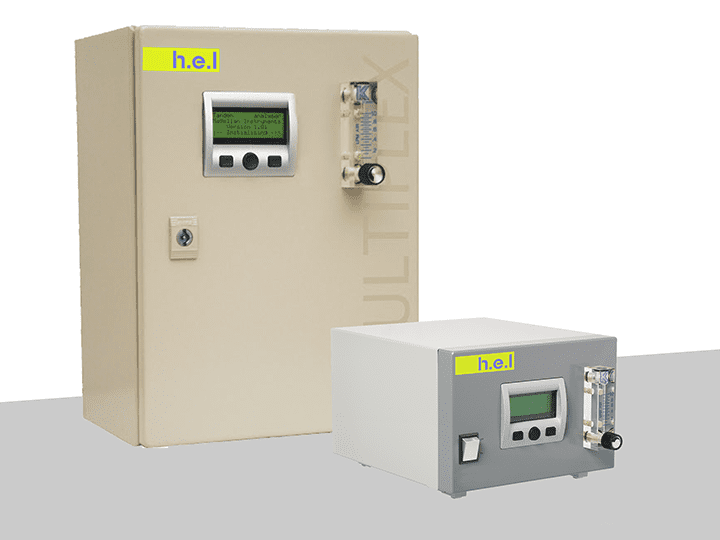

Tandem Off Gas Analyzers | Multi Line and Continuous Systems

The Tandem gas analyzer systems will give you real-time, on-line data that helps you under...

BioXplorer 400P | High-pressure bench-top, parallel 4 bioreactor platform

The BioXplorer 400P is an automated parallel pressure bioreactor system for the discovery ...

BioXplorer 400XL | Expanded Bench-Top, Parallel 8 Bioreactor Platform

Featuring eight 500 ml bioreactors, the BioXplorer 400XL allows the fast optimization of c...