Screening

How can the media feed be optimized?

Different strains have different medium requirements in terms of carbon and nitrogen sources, vitamins, and micro and micronutrients. However, different feeding strategies will also impact the growth and efficiency of cultures.

Batch feeding

This approach adds nutrients to the bioreactor in a single batch. It proves a controlled and defined nutrient environment for the screening process.

Fed-batch feeding

This type of feeding consists of continuous or intermittent feed addition throughout the cultivation process. Fed-batch feeding provides greater control over nutrient availability. Tuning the feed rate, nutrients, and compositions can result in significant growth, productivity, and product quality.

Continuous feeding

This approach consists of the continuous addition of feed of nutrients to the bioreaction at a constant rate throughout the process. This results in a controlled nutrient availability and growth rate, enhancing product performance.

Solutions

The BioXplorer is a powerful tool for screening processes. Its capabilities to control the different vessels (4 or 8, depending on the BioXplorer model) individually allow for evaluating different parameters, producing exceptionally accurate and detailed data. On the other hand, its integration with WinISO allows for the automatization of the process, reducing the risk of human error and the tight control of the conditions. This results in the generation of statistically robust data. Combining these capabilities, positions the BioXplorer as an invaluable tool for effective and efficient bioprocess screening.

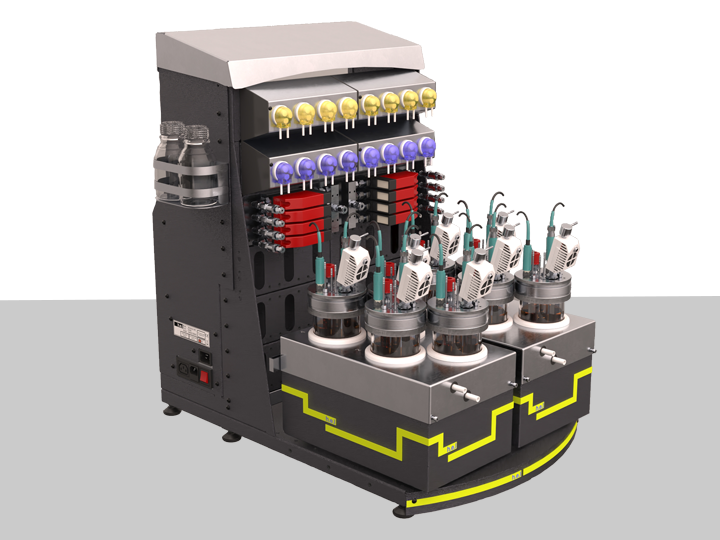

BioXplorer 100 | bench-top, parallel 8 bioreactor platform

The BioXplorer 100 is a multi-bioreactor system designed for the optimization of aerobic f...

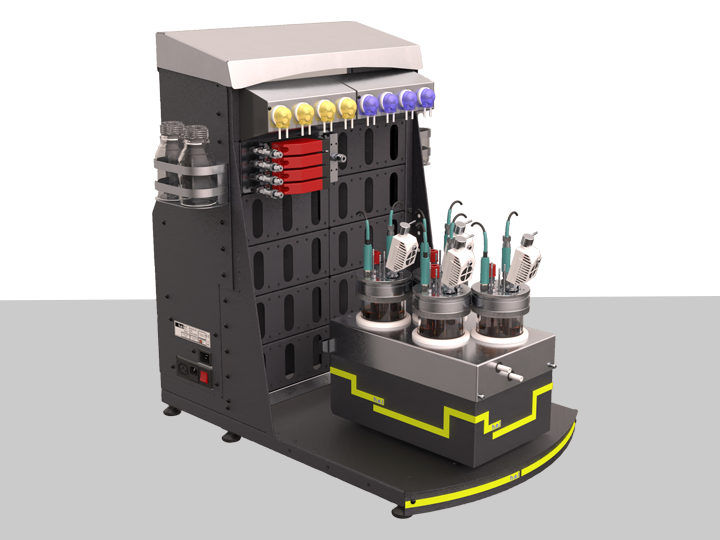

BioXplorer 400 | bench-top, parallel 4 bioreactor platform

The BioXplorer 400 is equipped with 4 bioreactors with working volumes of up to 400 ml. It...

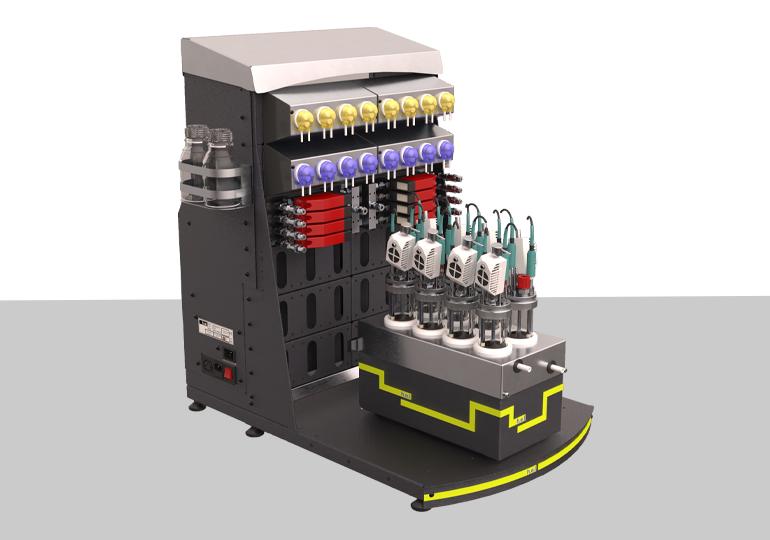

BioXplorer 400XL | Expanded Bench-Top, Parallel 8 Bioreactor Platform

Featuring eight 500 ml bioreactors, the BioXplorer 400XL allows the fast optimization of c...